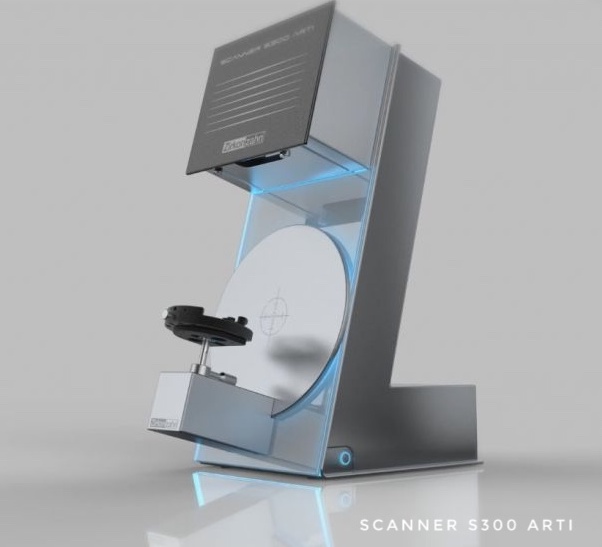

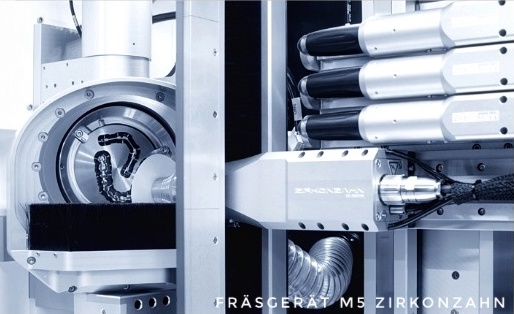

CAD/CAM technology (ZIRKONZAHN)

CAD/CAM dentures

Individual, custom-fit dentures using virtual modeling & high-tech manufacturing

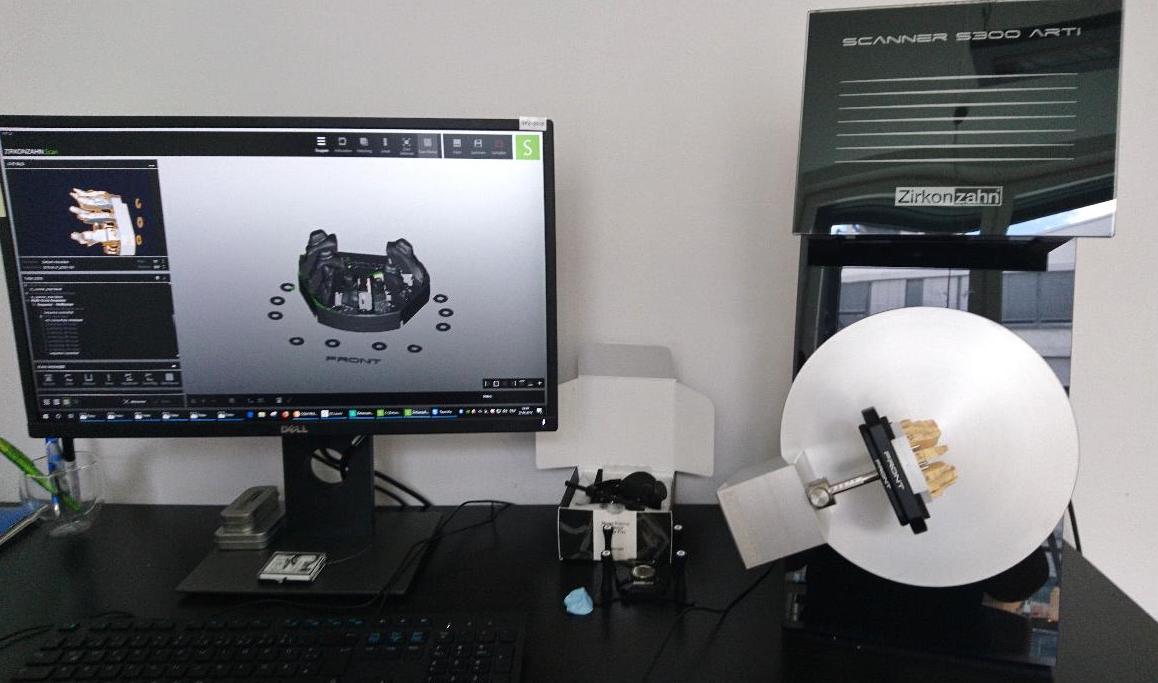

Technologies such as digital impressions, 3D X-rays and CAD/CAM are just a small selection of the dental trends that are currently having a significant impact on the practice and laboratory workflow.

The CAD/CAM method was originally used in the aerospace industry. However, the process is now used in many sectors, such as architecture, product design and even in the planning, design and production of high-quality dentures. CAD/CAM technology is currently the latest technological development in the field of restorative dentistry.

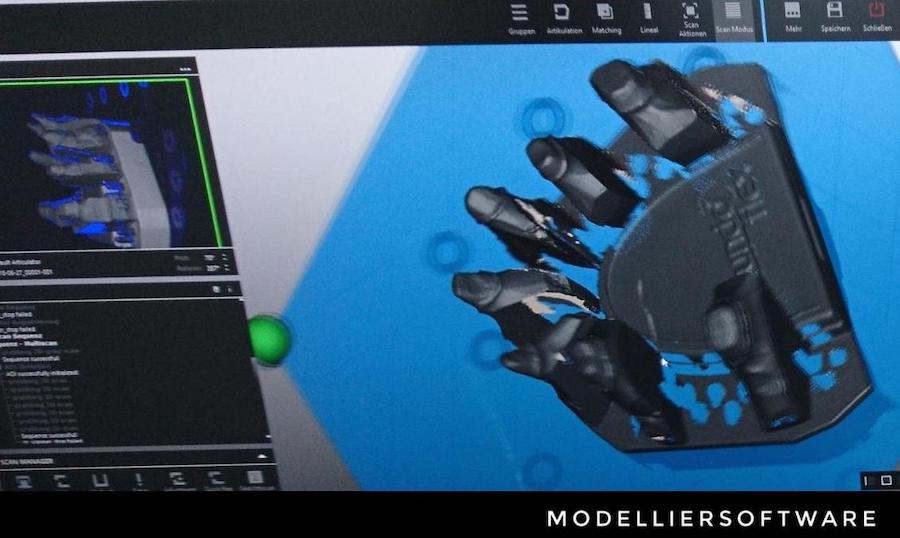

This computer-aided technology enables individualised tooth reconstructions and sophisticated implant prosthetics made of zirconium ceramics.

Zirconia ceramic dentures using the CAD/CAM process also available at Leipziger14 since June 2018

Thanks to the innovative, computer-aided process developed by Zirkonzahn founder Enrico Steger, we are able to manufacture your individual dentures not only accurately but also faster using high-tech production.

With the innovative devices, materials and technologies, Enrico Steger has not only realized his vision of anatomically and aesthetically perfect dentures, but also the dream of every patient.

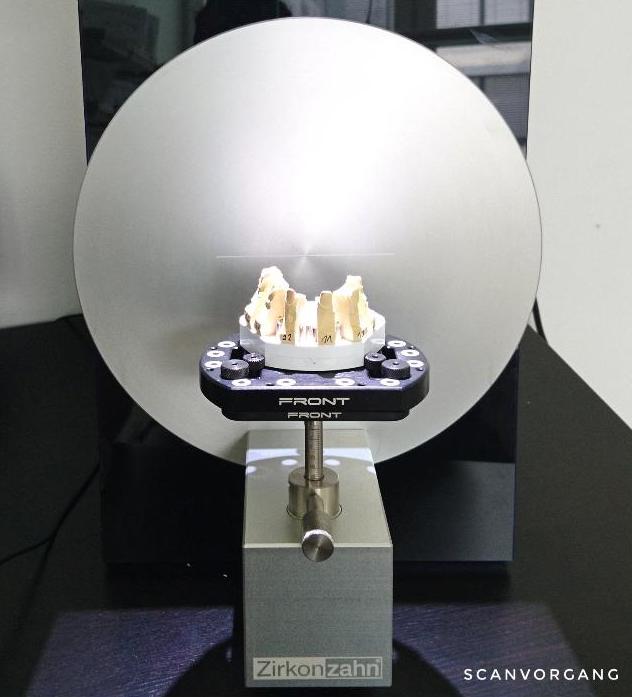

Procedure in our in-house dental laboratory

Using the latest technology, a precise, stable and biocompatible framework made of zirconium dioxide ceramic is produced there. Modern control technology enables a level of precision that humans cannot achieve, or can only achieve with disproportionately more effort. Zirconium dioxide ceramic enables outstanding esthetics and convincing accuracy of fit. The specifications from the CAD program are implemented precisely, and not just by eye, but to the nearest hundredth of a millimeter.

The dentures are then completed in our in-house dental laboratory. Our dental technician Alena Schmidt and our master dental technician Jost Schleser add the finishing touches to your dentures by veneering, glazing and matching coloring according to your wishes.

At Leipziger14, we attach great importance to ensuring that your dentures are made in German master quality! Particularly in the fields of dental technology, prosthetics and implantology, the CAD/CAM process enables better and therefore more cost-effective results to be achieved more quickly.

CAD/CAM dentures made of all-ceramic (zirconium oxide)

Zirconia is a miracle material that has opened up new dimensions for prosthetics. It is one of the oldest minerals on earth. The material used in medical applications is called zirconium oxide, which is obtained from zirconium sand in a complex process. Zirconium oxide is also used in prosthetics, but only in alloyed form. By adding yttrium oxide, a material is obtained that is characterized by high flexural strength, hardness and high resistance to chemical, thermal and mechanical influences. Highly esthetic, metal-free dental solutions become reality.

Advantages of the process

- tw. Unpleasant impression material can be dispensed with by scanning (intraoral scanner)

- High accuracy of fit due to machine production

- Cost-effective, because automatic production

- Fast production: shorter waiting time for you

Disadvantages

- Sometimes esthetically worse results than with hand-made dentures

- not suitable for all dentures: some shapes cannot be milled

Conclusion

Our specialists and dental technicians will be happy to welcome you on site to provide you with detailed advice and an assessment of whether CAD/CAM dentures are suitable for you.

Patient OPINIONS

Great doctor

Thorough diagnosis; honest recommendation not to carry out the planned special treatment in my case, thus saving me unnecessary treatment costs.

Friendly and competent

I felt safe and in good hands from the very first moment. Dr Planert took the time to answer my questions and explained everything clearly.

Outstanding!

I am completely satisfied! Very courteous reception... Advice and treatment at a very high level. Can recommend Leipziger14-Ihre Zahnärzte and Mr Planert with a clear conscience!"

Great doctor

Thorough diagnosis; honest recommendation not to carry out the planned special treatment in my case, thus saving me unnecessary treatment costs.

Outstanding!

I am completely satisfied! Very courteous reception... Advice and treatment at a very high level. Can recommend Leipziger14-Ihre Zahnärzte and Mr Planert with a clear conscience!"

Friendly and competent

I felt safe and in good hands from the very first moment. Dr Planert took the time to answer my questions and explained everything clearly.